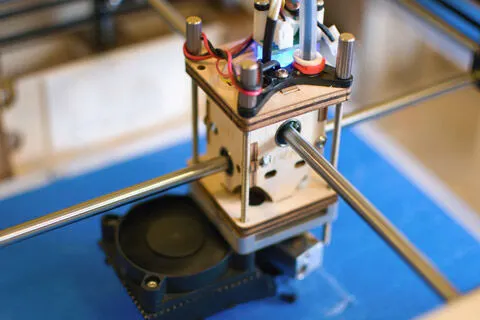

Additive Manufacturing

Additive manufacturing standards cover the full life cycle for printing an additively manufactured part, from 3 dimensional design input data through the selection of precursor materials; quality control during the printing process; post-processing; evaluating finished material properties; testing, qualification, and certification; and maintenance and repair. Materials used in additive manufacturing include metals, polymers, and ceramics and there are several different technologies and processes used to produce parts. Sectors actively using the technology include aerospace, defense, medical, electronics, and construction. Some standards developing organizations specialize in specific aspects. A sampling of available standards is provided below. Full search capabilities are available via the webstore. The America Makes and ANSI Additive Manufacturing Standardization Collaborative (AMSC) is a coordinating body that has published a roadmap (available as a free download) identifying published and needed standards to grow the additive manufacturing industry.

ASME Y14.46-2017

Product Definition for Additive Manufacturing

The Draft Standard, hereafter referred to as "Standard," covers definitions of terms and features unique to additive manufacturing (AM) technologies with recommendations for their uniform specification in product definition data sets and in related documents. Unless otherwise specified, any reference to features, parts, or processes shall be interpreted as applying to parts or assemblies manufactured using an AM process. Additively manufactured parts or assemblies are referred to as "parts" throughout the Standard. The Standard extends to capturing relevant AM detail from design, manufacturing, and quality engineering.

ISO/ASTM 52900:2021

Additive manufacturing - General principles - Fundamentals and vocabulary

This document establishes and defines terms used in additive manufacturing (AM) technology, which applies the additive shaping principle and thereby builds physical three-dimensional (3D) geometries by successive addition of material. The terms have been classified into specific fields of application.

ISO/ASTM 52901:2017

Additive manufacturing - General principles - Requirements for purchased AM parts

ISO/ASTM 52901:2017 defines and specifies requirements for purchased parts made by additive manufacturing.

ISO/ASTM 52901:2017 gives guidelines for the elements to be exchanged between the customer and the part provider at the time of the order, including the customer order information, part definition data, feedstock requirements, final part characteristics and properties, inspection requirements and part acceptance methods.

ISO/ASTM 52901:2017 is applicable for use as a basis to obtain parts made by additive manufacturing that meet minimum acceptance requirements. More stringent part requirements can be specified through the addition of one or more supplementary requirements at the time of the order.

ISO/ASTM 52910:2018

Additive manufacturing - Design - Requirements, guidelines and recommendations

This document gives requirements, guidelines and recommendations for using additive manufacturing (AM) in product design.

It is applicable during the design of all types of products, devices, systems, components or parts that are fabricated by any type of AM system. This document helps determine which design considerations can be utilized in a design project or to take advantage of the capabilities of an AM process.

General guidance and identification of issues are supported, but specific design solutions and process-specific or material-specific data are not supported.

The intended audience comprises three types of users:

— designers who are designing products to be fabricated in an AM system and their managers;

— students who are learning mechanical design and computer-aided design; and

— developers of AM design guidelines and design guidance systems.

ISO/ASTM 52915:2020

Specification for additive manufacturing file format (AMF) Version 1.2

This document provides the specification for the Additive Manufacturing File Format (AMF), an interchange format to address the current and future needs of additive manufacturing technology. This document specifies the requirements for the preparation, display and transmission for the AMF. When prepared in a structured electronic format, strict adherence to an extensible markup language (XML) [1] schema supports standards-compliant interoperability. NOTE A W3C XML schema definition (XSD) for the AMF is available from ISO from http://standards.iso.org/iso/52915 and from ASTM from www.astm.org/MEETINGS/images/amf.xsd. An implementation guide for such an XML schema is provided in Annex A. It is recognized that there is additional information relevant to the final part that is not covered by the current version of this document. Suggested future features are listed in Annex B. This document does not specify any explicit mechanisms for ensuring data integrity, electronic signatures and encryptions.

ISO/ASTM 52921:2013

Standard terminology for additive manufacturing - Coordinate systems and test methodologies

ISO/ASTM 52921:2013 includes terms, definitions of terms, descriptions of terms, nomenclature, and acronyms associated with coordinate systems and testing methodologies for additive manufacturing (AM) technologies in an effort to standardize terminology used by AM users, producers, researchers, educators, press/media, and others, particularly when reporting results from testing of parts made on AM systems. Terms included cover definitions for machines/systems and their coordinate systems plus the location and orientation of parts. It is intended, where possible, to be compliant with ISO 841 and to clarify the specific adaptation of those principles to additive manufacturing.

AWS D20.1/D20.1M:2019

Specification for Fabrication of Metal Components using Additive Manufacturing

This specification provides the general requirements for fabrication of metal components using additive manufacturing. It provides guidance for the interaction between the Engineer and the Contractor. It includes the design, qualification, fabrication, inspection, and acceptance of additively manufactured components. A commentary for the specification is included.

IPC/JPCA 2291-2013

Design Guideline for Printed Electronics

This guideline provides an overview of the design process flow for printed electronics based devices, modules and units, and final products. The intent of IPC/JPCA-2291 is to establish a design process flow that will facilitate and improve the practice of printed electronics design. IPC/JPCA-2291 identifies documents such as standards that can be used to assist during the design process flow.

IPC 2292-2018

Design Standard for Printed Electronics on Flexible Substrates

IPC-2292 standard establishes specific requirements for the design of printed electronic applications and their forms of component mounting and interconnecting structures on flexible substrates. Flexible substrates, as pertaining to IPC-2292 standard, are materials or devices which have some amount of flexibility or bendability (not rigid) but are not considered to be stretchable (e.g., fabrics, textiles stretchable polymers, etc.). IPC-2292 standard also defines three Standard Printed Electronic Designs (SPEDs) and includes an appendix with fabrication and design feature benefits and drawbacks.

IPC/JPCA 6901-2015

Application Categories for Printed Electronics

This standard establishes a Market Classification System and Level Classification System for printed electronics assemblies and provides a list of performance criteria and testing methods. It provides a standardized product category structure for designing and manufacturing printed electronics and assemblies which conform to industry-established performance metrics as determined by accepted testing methods.

IPC 6903A-2018

Terms and Definitions for the Design and Manufacture of Printed Electronics

The IPC-6903A standard provides 62 additional terms and definitions for the design and manufacture of printed electronics. The IPC-6903A standard creates a common language and understanding for the worldwide printed electronics community.

SAE AMS 7000-2018

Laser-Powder Bed Fusion (L-PBF) Produced Parts, Nickel Alloy, Corrosion and Heat-Resistant, 62Ni - 21.5Cr - 9.0Mo - 3.65Nb Stress Relieved, Hot Isostatic Pressed and Solution Annealed

This specification covers a corrosion and heat-resistant nickel alloy in the form of parts produced by laser-powder bed fusion (L-PBF) that are subjected to post-deposition stress relief (SR), hot isostatic press (HIP) and solution anneal operations. Parts may require subsequent machining or surface finishing to meet specific application requirements.

SAE AMS 7001-2018

Nickel Alloy, Corrosion and Heat-Resistant, Powder for Additive Manufacturing, 62Ni - 21.5Cr - 9.0Mo - 3.65Nb

This specification covers a corrosion and heat-resistant nickel alloy in the form of pre-alloyed powder.

SAE AMS 7002-2018

Process Requirements for Production of Metal Powder Feedstock for Use in Additive Manufacturing of Aerospace Parts

This specification is to prescribe process requirements for production of metal powder feedstock for use in additive manufacturing of aerospace parts.

SAE AMS 7003-2018

Laser Powder Bed Fusion Process

This specification establishes process controls for the repeatable production of aerospace parts by Laser Powder Bed Fusion (L-PBF). It is intended to be used for aerospace parts manufactured using Additive Manufacturing (AM) metal alloys, but usage is not limited to such applications.