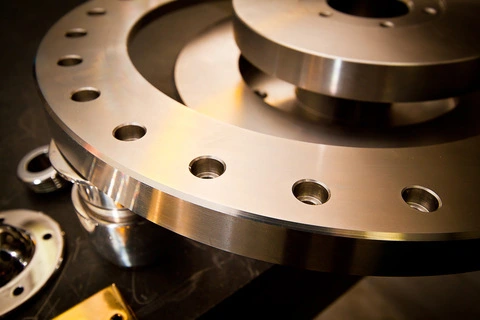

Aluminum Standards

Aluminum is known for being a lightweight and mallaeble metal. This material is used for many areas such as everyday cans and foil and even airplanes. Various aluminum alloys are produced to improve strength and other properties for particular applications. These standards cover specifics regarding aluminum in its many forms.