Other Explosive Atmosphere Standards

Other standards for explosive atmospheres deal with assorted topics, such as the safety requirements for the design and construction of reciprocating internal combustion engines for use in potentially explosive atmospheres. Similarly, the safety of industrial trucks is addressed, as is the design of fans working in such environments. Because of the dangerous nature of mining, special mention is given to equipment and components intended for use in potentially explosive atmospheres in underground mines.

ANSI/ISA 12.21.02-2013

Explosive Atmospheres - Part 28: Protection of equipment and transmission systems using optical radiation

This standard explains the potential ignition hazard from equipment using optical radiation intended for use in explosive gas and combustible dust atmospheres. It covers EPLs Ma, Mb, Ga, Gb, Gc, Da, Db and Dc. It also covers equipment, which itself is located outside but its emitted optical radiation enters such atmospheres. It describes precautions and requirements to be taken when using optical radiation transmitting equipment in explosive gas and combustible dust atmospheres. It also outlines a test method, which can be used to verify a beam is not ignition capable under selected test conditions, if the optical limit values cannot be guaranteed by assessment or beam strength measurement.

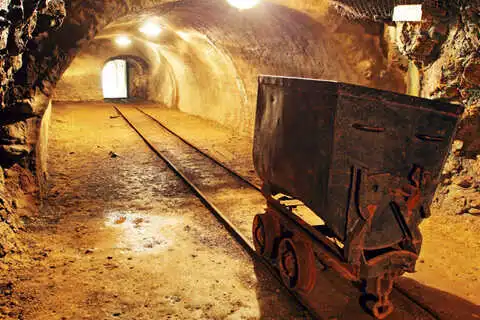

BS EN ISO/IEC 80079-38:2016+A1:2018

Explosive atmospheres. Equipment and components in explosive atmospheres in underground mines (British Standard)

ISO/IEC 80079-38:2016 is published as a dual logo standard and specifies the explosion protection requirements for the design, construction, assessment and information for use (maintenance, repair, marking) of equipment that may be an individual item or form an assembly. This includes machinery and components for use in mines susceptible to explosive atmospheres of firedamp and/or combustible dust. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that equipment can be operated are:- temperature -20 C to 60 C;- pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar);- and air with normal oxygen content, typically 21 % v/v. This part of ISO/IEC 80079 applies for equipment and components according to EPL Mb to be used in explosive atmospheres containing firedamp and/or combustible dust. For equipment and components according to EPL Ma, the requirements of this standard and of ISO 80079-36 and IEC 60079-0 apply. It is necessary to take account of external conditions to the equipment which may affect the hazard and the resultant protection measures. These measures may include ventilation, gas detection or gas drainage. This part of ISO/IEC 80079 also deals with the prevention of ignitions of explosive atmospheres caused by burning (or smouldering) of combustible material such as fabric fibres, plastic "O"-rings, rubber seals, lubricating oils or greases used in the construction of the equipment if such items could be an ignition source. For example, the mechanical failure of rotating shaft bearings can result in frictional heating that ignites its plastic cage, plastic seal or lubricating grease. Detailed requirements and test procedures for the fire protection of conveyer belts are not part of this part of ISO/IEC 80079. Keywords: explosive atmospheres in underground mines, combustible dust

BS EN 1834-1:2000

Reciprocating internal combustion engines. Safety requirements for design and construction of engines for use in potentially explosive atmospheres. Group II engines for use in flammable gas and vapour atmospheres (British Standard)

This European standard specifies the safety requirements and/or measures to remove the hazards and limit the risks on reciprocating internal combustion compression ignition engines hereinafter referred to as "engines" of group II categories 2 and 3 for use in potentially explosive atmospheres of flammable gas and vapour. This European standard does not apply to flammable gas and vapour atmospheres containing carbon disulphide (CS2).

ANSI/ISA 12.20.01-2009 (R2014)

General Requirements for Electrical Ignition Systems for Internal Combustion Engines in Class I, Division 2 or Zone 2, Hazardous (Classified) Locations

This standard is intended to enhance the safety of personnel by providing minimum requirements for electrical ignition systems for spark-ignited reciprocating internal combustion engines, parts of which are installed or operated in Class I, Division 2 or Zone 2 hazardous (classified) locations.

BS EN 1834-2:2000

Reciprocating internal combustion engines. Safety requirements for design and construction of engines for use in potentially explosive atmospheres. Group I engines for use in underground workings susceptible to firedamp and/or combustible dust (British Standard)

This European standard specifies the safety requirements and/or measures to remove the hazards and limit the risks on reciprocating internal combustion compression ignition engines of group I category M2 for use in underground workings susceptible to firedamp and/or combustible dust hereinafter referred to as engines. The standard does not define requirements relating to the driven machinery.

BS EN 1834-3:2000

Reciprocating internal combustion engines. Safety requirements for design and construction of engines for use in potentially explosive atmospheres. Group II engines for use in flammable dust atmospheres (British Standard)

This European standard specifies the safety requirements and/or measures to remove the hazards and limit the risks on reciprocating internal combustion compression ignition engines of group II categories 2 and 3 for use in flammable dust atmospheres. The standard does not define requirements relating to the driven machinery. These requirements can be found in the appropriate application standards.