BPVC Standards Subscription from ANSI

2021 Edition ASME Boiler and Pressure Vessel Codes

ASME Boiler and Pressure Vessel Codes Standards Subscriptions provide your organization with convenient and cost-effective multi-user access to just the standards you need. Create a Standards Subscription by selecting standards from different standards developers (SDOs) or by selecting specific ASME Boiler and Pressure Vessel Codes standards. Licensed collections can be referenced by your entire staff from any PC in the world. Multi-year agreements offer additional savings and lock in pricing. Revisions of licensed standards are automatically provided as they are updated during your subscription term.

BPVC Section II – Materials

BPVC Section III-Rules for Construction of Nuclear Facility Component

BPVC Section IV-Rules for Construction of Heating Boilers

BPVC Section V-Nondestructive Examination

BPVC Section VI-Recommended Rules for the Care and Operation of Heating Boilers

BPVC Section VII-Recommended Guidelines for the Care of Power Boilers

BPVC Section VIII-Rules for Construction of Pressure Vessels

BPVC Section IX-Welding, Brazing, and Fusing Qualifications

BPVC Section X-Fiber-Reinforced Plastic Pressure Vessels

BPVC Section XI-Rules for Inservice Inspection of Nuclear Power Plant Components

BPVC Section XII-Rules for Construction and Continued Service of Transport Tanks

BPVC Section XIII-Rules for Overpressure Protection

BPVC Section I – Rules for Construction of Power Boilers

This Section provides requirements for all methods of construction of power, electric, and miniature boilers; high temperature water boilers, heat recovery steam generators, and certain fired pressure vessels to be used in stationary service; and power boilers used in locomotive, portable, and traction service. Rules pertaining to use of the ASME Certification Mark and V, A, M, PP, S and E Designators are also included. The rules are applicable to boilers in which steam or other vapor is generated at a pressures exceeding 15 psig, and high temperature water boilers intended for operation at pressures exceeding 160 psig and/or temperatures exceeding 250 degree F. Superheaters, economizers, and other pressure parts connected directly to the boiler without intervening valves are considered as part of the scope of Section I.

BPVC Section II – Materials

This Section is a “Service Section” to the other BPVC Sections, providing material specifications for ferrous materials adequate for safety in the field of pressure equipment. These specifications contain requirements for chemical and mechanical properties, heat treatment, manufacture, heat and product analyses, and methods of testing. It also provides material specifications for the manufacture, acceptability, chemical composition, mechanical usability, surfacing, testing requirements and procedures, operating characteristics, and intended uses for welding rods, electrodes and filler metals. Later parts define tables of material properties including allowable, design, tensile and yield stress values, physical properties and external pressure charts and tables.

BPVC Section III-Rules for Construction of Nuclear Facility Component

This Subsection contains requirements for the material, design, fabrication, examination, testing and overpressure protection of items which are intended to conform to the requirements for Class 1, 2, and MC construction. Nuclear power plant supports for which rules are specified are those metal supports which are designed to transmit loads from the pressure retaining barrier of the component or piping to the load carrying building structure. In some cases there may be intervening elements in the component support load path which are not constructed to the rules of this Section, such as diesel engines, electric motors, valve operators, coolers, and access structures. This section covers quality assurance requirements, ASME Product Certification Marks, and authorized inspection for Class 1, 2, 3, MC, CS, and CC construction, including selective reference of ASME Standard NQA-1, Quality Assurance Program Requirements for Nuclear Facilities, and requirements for the material, design, construction, fabrication, testing, examination, and overpressure protection of concrete containment structures, pre-stressed or reinforced. Later topics include design and construction of the containment systems for nuclear spent fuel or high-level radioactive material transport packaging.

BPVC Section IV-Rules for Construction of Heating Boilers

This Section provides requirements for design, fabrication, installation and inspection of steam heating, hot water heating, hot water supply boilers, and potable water heaters intended for low pressure service that are directly fired by oil, gas, electricity, coal or other solid or liquid fuels. It contains appendices which cover approval of new material, methods of checking safety valve and safety relief valve capacity, examples of methods of checking safety valve and safety relief valve capacity, examples of methods of calculation and computation, definitions relating to boiler design and welding, and quality control systems. Rules pertaining to use of the H, HV, and HLW ASME Product Certification Marks are also included.

BPVC Section V-Nondestructive Examination

This Section contains requirements and methods for nondestructive examination which are referenced and required by other BPVC Sections. It also includes manufacturer's examination responsibilities, duties of authorized inspectors and requirements for qualification of personnel, inspection and examination. Examination methods are intended to detect surface and internal discontinuities in materials, welds, and fabricated parts and components. A glossary of related terms is included.

BPVC Section VI-Recommended Rules for the Care and Operation of Heating Boilers

This Section covers general descriptions, terminology and operation guidelines applicable to steel and cast iron boilers limited to the operating ranges of Section IV Heating Boilers. It includes guidelines for associated controls and automatic fuel burning equipment. Illustrations show typical examples of available equipment. Also included is a glossary of terms commonly associated with boilers, controls, and fuel burning equipment.

BPVC Section VII-Recommended Guidelines for the Care of Power Boilers

The purpose of these recommended guidelines is to promote safety in the use of power boilers. The term “power boiler” in this Section includes stationary, portable, and traction type boilers, but does not include locomotive and high temperature water boilers, nuclear power plant boilers, heating boilers, pressure vessels, or marine boilers. This Section provides such guidelines to assist those directly responsible for operating, maintaining, and inspecting power boilers. Emphasis has been placed on industrial type boilers because of their extensive use. Guidelines are also provided for operation of auxiliary equipment and appliances that affect the safe and reliable operation of power boilers.

BPVC Section VIII-Rules for Construction of Pressure Vessels

This Division of Section VIII provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Such pressure vessels may be fired or unfired. Specific requirements apply to several classes of material used in pressure vessel construction, and also to fabrication methods such as welding, forging and brazing. It contains mandatory and nonmandatory appendices detailing supplementary design criteria, nondestructive examination and inspection acceptance standards. Rules pertaining to the use of the U, UM and UV ASME Product Certification Marks are also included. Other sections provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Such vessels may be fired or unfired. This pressure may be obtained from an external source or by the application of heat from a direct or indirect source, or any combination thereof. These rules provide an alternative to the minimum requirements for pressure vessels under Division 1 rules. In comparison the Division 1, Division 2 requirements on materials, design, and nondestructive examination are more rigorous; however, higher design stress intensify values are permitted. Division 2 rules cover only vessels to be installed in a fixed location for a specific service where operation and maintenance control is retained during the useful life of the vessel by the user who prepares or causes to be prepared the design specifications. These rules may also apply to human occupancy pressure vessels typically in the diving industry. Rules pertaining to the use of the U2 and UV ASME Product Certification Marks are also included. Later topics include requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures generally above 10,000 psi. Such vessels may be fired or unfired. This pressure may be obtained from an external source, a process reaction, by the application of heat from a direct or indirect source, or any combination thereof. Division 3 rules cover vessels intended for a specific service and installed in a fixed location or relocated from work site to work site between pressurizations. The operation and maintenance control is retained during the useful life of the vessel by the user who prepares or causes to be prepared the design specifications. Division 3 does not establish maximum pressure limits for either Section VIII, Divisions 1 or 2, nor minimum pressure limits for this Division. Rules pertaining to the use of the UV3 ASME Product Certification Marks are also included.

BPVC Section IX-Welding, Brazing, and Fusing Qualifications

This Section contains rules relating to the qualification of welding, brazing, and fusing procedures as required by other BPVC Sections for component manufacture. It also covers rules relating to the qualification and requalification of welders, brazers, and welding, brazing and fusing machine operators in order that they may perform welding, brazing, or plastic fusing as required by other BPVC Sections in the manufacture of components. Welding, brazing, and fusing data cover essential and nonessential variables specific to the joining process used.

BPVC Section X-Fiber-Reinforced Plastic Pressure Vessels

This Section provides requirements for construction of an FRP pressure vessel in conformance with a manufacturer's design report. It includes production, processing, fabrication, inspection and testing methods required for the vessel. Section X includes three Classes of vessel design; Class I and Class III - qualification through the destructive test of a prototype and Class II - mandatory design rules and acceptance testing by nondestructive methods. These vessels are not permitted to store, handle or process lethal fluids. Vessel fabrication is limited to the following processes: bag-molding, centrifugal casting and filament-winding and contact molding. General specifications for the glass and resin materials and minimum physical properties for the composite materials are given.

BPVC Section XI-Rules for Inservice Inspection of Nuclear Power Plant Components

Provides requirements to maintain the nuclear power plant while in operation and to return the plant to service following plant outages. The rules require a mandatory program to evidence adequate safety and manage deterioration and aging effects. The rules also stipulate duties of the Authorized Nuclear Inservice Inspector to verify that the mandatory program has been completed, permitting the plant to return to service in a safe and expeditious manner. Application of this Section begins when the requirements of the construction code have been satisfied.

DIVISION 1

This Division provides rules for the examination, inspection, and testing; NDE methods, qualifications, and requirements; evaluation and acceptance standards for flaws, defects, and relevant conditions; repair/replacement processes and correction actions/measures in light water cooled nuclear power plants.

DIVISION 2

This Division provides the requirements for the creation of the Reliability and Integrity Management (RIM) Program for advanced nuclear reactor designs. The RIM Program addresses the entire life cycle for all types of nuclear power plants, it requires a combination of monitoring, examination, tests, operation, and maintenance requirements that ensures each Structure, System, and Component (SSC) meets plant risk and reliability goals that are selected for the RIM Program.

BPVC Section XII-Rules for Construction and Continued Service of Transport Tanks

This Section covers requirements for construction and continued service of pressure vessels for the transportation of dangerous goods via highway, rail, air or water at pressures from full vacuum to 3,000 psig and volumes greater than 120 gallons. "Construction" is an all-inclusive term comprising materials, design, fabrication, examination, inspection, testing, certification, and over-pressure protection. "Continued service" is an all-inclusive term referring to inspection, testing, repair, alteration, and recertification of a transport tank that has been in service. This Section contains modal appendices containing requirements for vessels used in specific transport modes and service applications. Rules pertaining to the use of the T ASME Product Certification Marks are included.

BPVC Section XIII-Rules for Overpressure Protection

This Section provides rules for the overpressure protection of pressurized equipment such as boilers, pressure vessels, and piping systems. This standard provides requirements for topics such as design, material, inspection, assembly, testing, and marking for pressure relief valves, rupture disk devices, pin devices, spring-actuated non-reclosing devices, and temperature and pressure relief valves. This standard also covers devices in combination, capacity and flow resistance certification, authorization to use the ASME Certification Mark, installation, and overpressure protection by system design.

ASHRAE, the American Society of Heating, Refrigerating and Air Conditioning Engineers, is a nonprofit organization that develops and publishes standards for the heating, ventilating and air conditioning industry. Headquartered in Atlanta, United States, ASHRAE is an international society with over 50,000 members. ASHRAE standards are spread by its heavy involvement in Washington D.C. and with its wide assortment of international events. ASHRAE also serves as the administrator for the U.S. TAGs (United States Technical Advisory Group) to ISO/TCs 86, 142, 180 and 205 (International Organization for Standardization/Technical Committee) and tmany of the subcommittees for ISO/TCs 86 and 180.

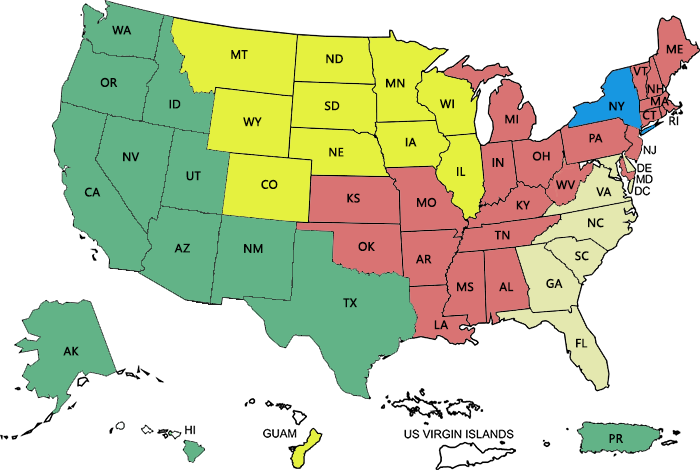

For sales inquiries regarding standards subscriptions, please contact our team:

Find Out About the Benefits of ANSI Standards Subscription

Canada: AB, BC, NT, SK, YT

Central & South America: ALL

Mexico: ALL

Caribbean: ALL

Asia: SOUTH, PACIFIC

Europe: ALL

Asia: MIDDLE EAST

Africa: ALL

Canada: MB, ON, QC, NB, NL, PE