Most recent

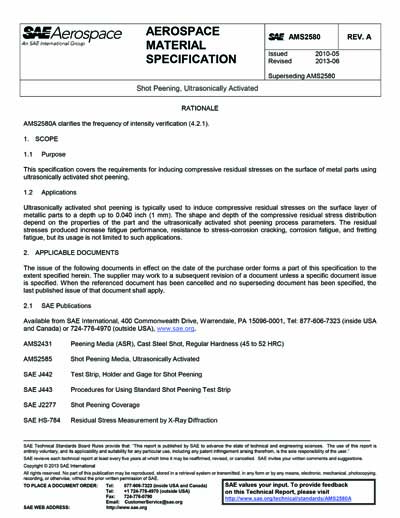

SAE AMS 2580A-2013 (SAE AMS2580A-2013)

Shot Peening, Ultrasonically Activated

This specification covers the requirements for inducing compressive residual stresses on the surface of metal parts using ultrasonically activated shot peening.

Ultrasonically activated shot peening is typically used to induce compressive residual stresses on the surface layer of metallic parts to a depth up to 0.040 inch (1 mm). The shape and depth of the compressive residual stress distribution depend on the properties of the part and the ultrasonically activated shot peening process parameters. The residual stresses produced increase fatigue performance, resistance to stress-corrosion cracking, corrosion fatigue, and fretting fatigue, but its usage is not limited to such applications.

Content Provider

Society of Automotive Engineers [sae]