Hearing Protection Standards

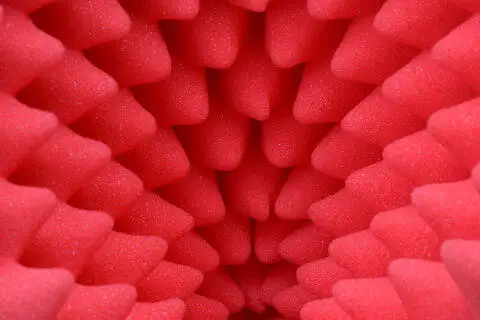

Hearing Protection Standards guide noise safety when noise cannot be sufficiently reduced due to the intrinsic properties of a particular action or environment. Tools used at, for example, construction sites, frequently cannot be made any quieter, and the worker’s proximity to the tool means the sound cannot readily be attenuated either. This leaves the utilization of hearing protection as a major component of a noise safety arsenal. Other times, people are only temporarily subjected to loud noises, making it so that the use of individual hearing protection is more effective than dealing with the noise itself. Key examples of this case are demolitions, where the noise is very loud but short lived, or rooms that are always loud but only require human presence at limited intervals.