Noise Control Safety Standards

Noise Control Safety Standards come into play when the generation of noise cannot be avoided and must be addressed in some manner. Common solutions include the use of silencers or enclosures/cabins. Noise control is vital to protecting the safety of workers, as well as the comfort levels of those outside the workplace but still close enough to be affected.

AGMA 914-B04

Gear Sound Manual - Part I: Fundamentals of Sound as Related to Gears; Part II: Sources, Specifications and Levels of Gear Sound; Part III: Gear Noise Control

This information sheet discusses how noise measurement and control depend upon the individual characteristics of the prime mover, gear unit, and driven machine, as well as their combined effects in a particular acoustical environment. It indicates certain areas that might require special attention. This document is a revision of AGMA 299.01 to include updated references and a discussion of Fast Fourier Transform analysis.

AS 2436-2010 (R2016)

Guide to noise and vibration control on construction, demolition and maintenance sites (FOREIGN STANDARD)

RECONFIRMATION NOTICE Technical Committee EV-010 has reviewed the content of this publication and in accordance with Standards Australia procedures for reconfirmation, it has been determined that the publication is still valid and does not require change. Certain documents referenced in the publication may have been amended since the original date of publication. Users are advised to ensure that they are using the latest versions of such documents as appropriate, unless advised otherwise in this Reconfirmation Notice. Approved for reconfirmation in accordance with Standards Australia procedures for reconfirmation on 31 May 2016. The following are represented on Technical Committee EV-010: Acoustical Society of New Zealand Association of Australian Acoustical Consultants Australian Acoustical Society AUSTROADS Bureau of Steel Manufacturers of Australia Department of Defence (Australian Government) Master Builders Australia Ministry of Health (NZ) National Acoustic Laboratories The University of Sydney

AS/NZS 1269.2:2005 (R2016)

Occupational noise management - Noise control management (FOREIGN STANDARD)

Sets outs requirements and guidance on the management of noise control in occupational settings and applies to all types of workplaces and to all types of sounds. RECONFIRMATION NOTICE Technical Committee AV-003 has reviewed the content of this publication and in accordance with Standards Australia procedures for reconfirmation, it has been determined that the publication is still valid and does not require change. Certain documents referenced in the publication may have been amended since the original date of publication. Users are advised to ensure that they are using the latest versions of such documents as appropriate, unless advised otherwise in this Reconfirmation Notice. Approved for reconfirmation in accordance with Standards Australia procedures for reconfirmation on 7 December 2015. Approved for reconfirmation in New Zealand on behalf of the Standards Council of New Zealand on 18 May 2016. The following are represented on Technical Committee AV-003: Accident Compensation Corporation (New Zealand) Association of Australian Acoustical Consultants Australian Acoustical Society Australian Chamber of Commerce and Industry Australian Council of Trade Unions Department of Defence (Australian Government) Engineers Australia Ministry of Health (NZ) National Acoustic Laboratories New South Wales Nurses' Association New Zealand Audiological Society Worksafe Division, Department of Commerce, Western Australia WorkSafe Victoria

BS 5228-1:2009+A1:2014

Code of practice for noise and vibration control on construction and open sites. Noise (British Standard)

BS 5228-2:2009+A1:2014

Code of practice for noise and vibration control on construction and open sites. Vibration (British Standard)

DIN 45635-12:1978

Measurement of noise emitted by machines; Airborne noise measurement, enveloping surface method; Electrical switchgear and control gear (FOREIGN STANDARD)

ISO 14163:1998

Acoustics - Guidelines for noise control by silencers

This International Standard deals with the practical selection of silencers for noise control in gaseous media. It specifies the acoustical and operational requirements which are to be agreed upon between the supplier or manufacturer and the user of a silencer. The basic principles of operation are described in this International Standard, but it is not a silencer design guide. The silencers described are suitable, among others, for attenuating system noise and preventing crosstalk in heating, ventilation and air-conditioning (HVAC) equipment; for preventing or reducing sound transmission through ventilation openings from rooms with high inside sound levels; for attenuating blow-off noise generated by high-pressure lines; for attenuating intake and exhaust noise generated by internal combustion engines; and for attenuating intake and outlet noise from fans, compressors and turbines. They are classified according to their types, performance characteristics and applications. Active and adaptive passive noise-control systems are not covered in detail in this International Standard.

ISO 15664:2001

Acoustics -- Noise control design procedures for open plant

This International Standard defines the procedures for noise control of mainly open plants. It is applicable to the following: specification of procedures for noise control during engineering of a new plant and modification/extension of existing plants (construction noise procedures are outside the scope of this International Standard but should be considered); definition of responsibilities of parties involved, viz. end-user , engineering contractor and equipment supplier ; description of general procedures to arrive at noise requirements for individual equipment, on the basis of overall noise requirements for the plant. A schematic flowchart, reviewing the noise control process, is presented in annex A and a summary of action items is presented in annex B.

ISO 15667:2000

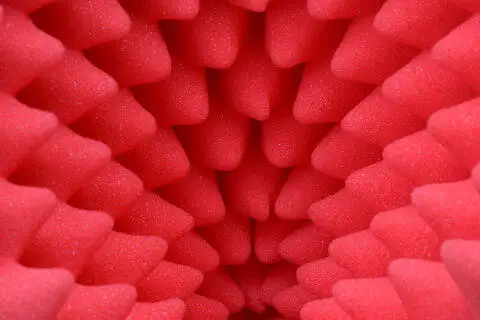

Acoustics -- Guidelines for noise control by enclosures and cabins

This International Standard deals with the performance of enclosures and cabins designed for noise control. It outlines the acoustical and operational requirements which are to be agreed upon between the supplier or manufacturer and the user of such enclosures and cabins. This International Standard is applicable to two types of acoustic enclosures and cabins, as follows. Cabins for noise protection of operators: free-standing cabins and cabins attached to machines (e.g. vehicles, cranes). Free-standing enclosures covering or housing machines: enclosures with a fraction of acoustically untreated open area of less than 10 % of the total surface are the main subject of this International Standard. In this International Standard, emphasis is put on lightweight constructions. However, thick, massive structures as, for example, brick walls, are not excluded. Enclosures and cabins with more than 10 % open and untreated area belong to the category of partial enclosures. They are not the subject of this International Standard. A third type of enclosure, integrated enclosures which form a part of the machine and are firmly attached to it, is not the subject of this International Standard.

ISO 17624:2004

Acoustics - Guidelines for noise control in offices and workrooms by means of acoustical screens

ISO 17624:2004 deals with the effectiveness of acoustical screens. It specifies the acoustical and operational requirements to be agreed upon between the supplier or manufacturer and the user of acoustical screens. ISO 17624:2004 is applicable to the following types of acoustical screens: free-standing acoustical screens for offices, service areas, exhibition areas, and similar rooms; acoustical screens integrated in the furniture of such rooms; portable and removable acoustical screens for workshops; fixed room partitions with more than 10 % of the connecting area open and acoustically untreated. Walls of partial acoustic enclosures and cabins which, together with the room boundary surfaces, also partition a room and provide more than 10 % open and acoustically untreated area, are also treated as acoustical screens. ISO 17624:2004 is not applicable to cabinet walls and similar multi-layer walls whose thickness exceeds 0,2 m, nor to banners and other types of suspended baffles.