Most recent

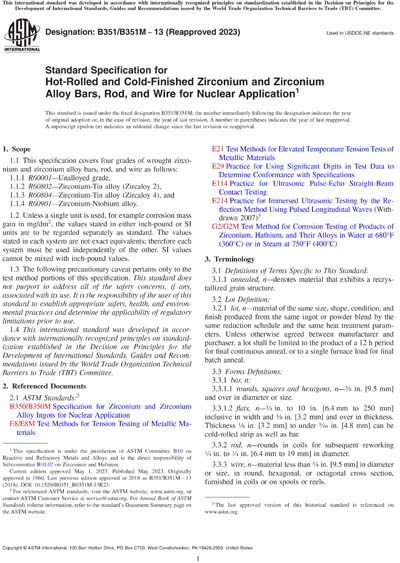

ASTM B351/B351M-13(2023)

Standard Specification for Hot-Rolled and Cold-Finished Zirconium and Zirconium Alloy Bars, Rod, and Wire for Nuclear Application

This specification covers UNS R60001, R60802, R60804, and R60901 wrought zirconium and zirconium alloy bars, rods, and wires. All material grades covered should conform to the required chemical composition requirements. Elements that are intentionally added to the melt should be identified, analyzed and reported in the chemical analysis. The zirconium and zirconium alloys should be made from ingots produced by vacuum or plasma arc melting, vacuum electron-beam melting, a combination of the three methods, or other melting processes conventionally used for reactive metals. All processes should be performed in furnaces specifically for reactive metals. Mill products included in this specification should be formed with conventional extrusion, forging, or rolling equipment that is used in primary ferrous and nonferrous plants. The cold worked and annealed materials should be in fully annealed condition unless otherwise specified. Hot worked shapes should be furnished in not descaled, mechanically descaled, or mechanically descaled and pickled finish, while cold-worked shapes should be furnished in cold-worked, ground, or pickled finish.

ASTM International [astm]