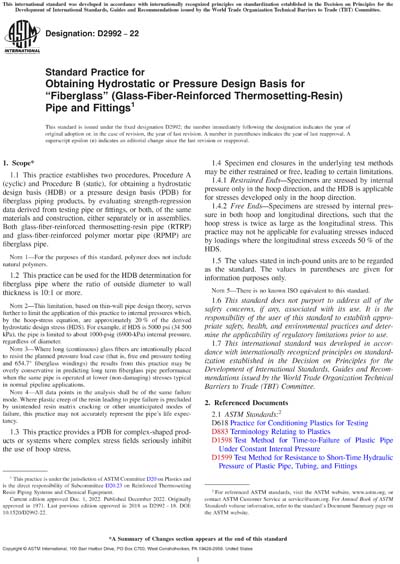

Historical

ASTM D2992-22

Standard Practice for Obtaining Hydrostatic or Pressure Design Basis for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Fittings

1.1This practice establishes two procedures, Procedure A (cyclic) and Procedure B (static), for obtaining a hydrostatic design basis (HDB) or a pressure design basis (PDB) for fiberglass piping products, by evaluating strength-regression data derived from testing pipe or fittings, or both, of the same materials and construction, either separately or in assemblies. Both glass-fiber-reinforced thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipe.

Note 1:For the purposes of this standard, polymer does not include natural polymers.

1.2This practice can be used for the HDB determination for fiberglass pipe where the ratio of outside diameter to wall thickness is 10:1 or more.

Note 2:This limitation, based on thin-wall pipe design theory, serves further to limit the application of this practice to internal pressures which, by the hoop-stress equation, are approximately 20 % of the derived hydrostatic design stress (HDS). For example, if HDS is 5000 psi (34 500 kPa), the pipe is limited to about 1000-psig (6900-kPa) internal pressure, regardless of diameter.

Note 3:Where long (continuous) glass ï¬bers are intentionally placed to resist the planned pressure load case (that is, free end pressure testing and 654.7° ï¬berglass windings) the results from this practice may be overly conservative in predicting long term ï¬berglass pipe performance when the same pipe is operated at lower (non-damaging) stresses typical in normal pipeline applications.

Note 4:All data points in the analysis shall be of the same failure mode. Where plastic creep of the resin leading to pipe failure is precluded by unintended resin matrix cracking or other unanticipated modes of failure, this practice may not accurately represent the pipe's life expectancy.

1.3This practice provides a PDB for complex-shaped products or systems where complex stress fields seriously inhibit the use of hoop stress.

1.4Specimen end closures in the underlying test methods may be either restrained or free, leading to certain limitations.

1.4.1Restrained Ends - Specimens are stressed by internal pressure only in the hoop direction, and the HDB is applicable for stresses developed only in the hoop direction.

1.4.2Free Ends - Specimens are stressed by internal pressure in both hoop and longitudinal directions, such that the hoop stress is twice as large as the longitudinal stress. This practice may not be applicable for evaluating stresses induced by loadings where the longitudinal stress exceeds 50 % of the HDS.

1.5The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information purposes only.

Note 5:There is no known ISO equivalent to this standard.

1.6This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM International [astm]