Historical

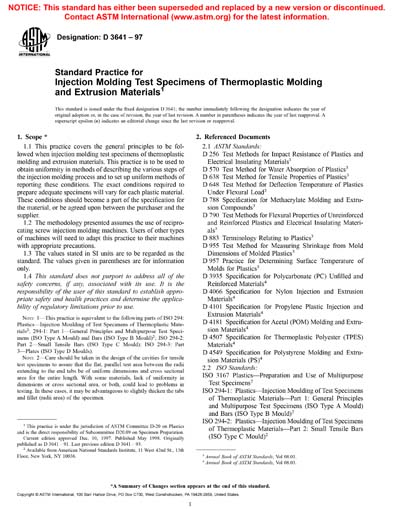

ASTM D3641-97

Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials

This practice covers the general principles to be followed when injection molding test specimens of thermoplastic molding and extrusion materials. This practice is to be used to obtain uniformity in methods of describing the various steps of the injection molding process and to set up uniform methods of reporting these conditions. The exact conditions required to prepare adequate specimens will vary for each plastic material. These conditions should become a part of the specification for the material, or be agreed upon between the purchaser and the supplier. This practice is similar in content (but not technically equivalent) to ISO 294-1975 (E). 1.2 The methodology presented assumes the use of reciprocating screw injection molding machines. Users of other types of machines will need to adapt this practice to their machines with appropriate precautions. 1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1- This practice is equivalent to the following parts of ISO 294: Plastics-Injection Moulding of Test Specimens of Thermoplastic Materials2, 294-1: Part 1- General Principles and Multipurpose Test Specimens (ISO Type A Mould) and Bars (ISOType B Mould)2, ISO 294-2: Part 2 - Small Tensile Bars (ISO Type C Mould)2, ISO 294-3: Part 3 - Plates (ISO Type D Moulds)2. Note 2 - Care should be taken in the design of the cavities for tensile test specimens to assure that the flat, parallel test area between the radii extending to the end tabs be of uniform dimensions and cross sectional area for the entire length. With some materials, lack of uniformity in dimensions or cross sectional area, or both, could lead to problems in testing. In these cases, it may be advantageous to slightly thicken the tabs and fillet (radii area) of the specimen.

ASTM International [astm]