Historical

ASTM F899-09

Standard Specification for Wrought Stainless Steels for Surgical Instruments

1.1 This specification covers the chemistry requirements for wrought stainless steels used for the manufacture of surgical instruments. The data contained in Tables 1-4 of this specification, including typical hardness values, common heat treating cycles, and examples of selected stainless steels that have been used for surgical instruments, is provided for reference only. Mechanical property requirements, heat treating requirements, hardness requirements and all other requirements except chemistry are governed by the appropriate material standards as referenced below or as agreed upon between purchaser and supplier.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

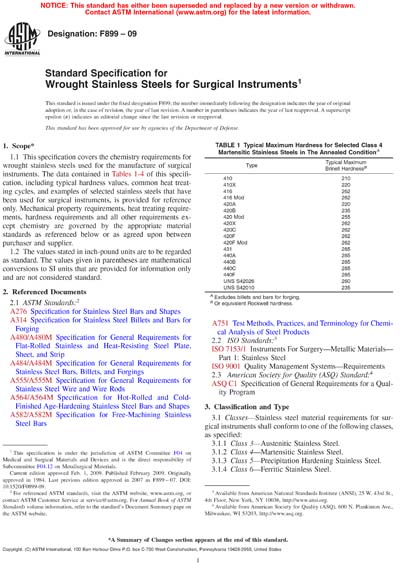

TABLE 1 Typical Maximum Hardness for Selected Class 4 Martensitic Stainless Steels in The Annealed ConditionA

| Type | Typical Maximum Brinell HardnessB |

| 410 | 210 |

| 410X | 220 |

| 416 | 262 |

| 416 Mod | 262 |

| 420A | 220 |

| 420B | 235 |

| 420 Mod | 255 |

| 420X | 262 |

| 420C | 262 |

| 420F | 262 |

| 420F Mod | 262 |

| 431 | 285 |

| 440A | 285 |

| 440B | 285 |

| 440C | 285 |

| 440F | 285 |

| UNS S42026 | 260 |

| UNS S42010 | 235 |

A Excludes billets and bars for forging.

B Or equivalent Rockwell hardness.

TABLE 2 Typical Heat Treating Cycles and Resultant Hardness Values for Selected Class 4 Martensitic Stainless Steels

| Type | Typical HardeningA Heat Treatment | Typical Hardness at Indicated Tempering TemperatureB | Type | Typical HardeningA Heat Treatment | Typical Hardness at Indicated Tempering TemperatureB | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °F | °C | (HRC) | °F | °C | (HRC) | ||||||

| 410 | 1850°F (1010°C) + | 500 | 260 | 43 | 420C | 1900°F (1038°C) + | 300 | 149 | 58 | ||

| Oil quench | 700 | 371 | 43 | Warm oil quench | 400 | 204 | 55/56 | ||||

| or air cool | 900C | 482 | 42 | 500 | 260 | 53/54 | |||||

| 1000C | 538 | 30 | 600 | 315 | 53/54 | ||||||

| 1100 | 593 | 24 | 700 | 371 | 54/55 | ||||||

| 410X | 1875°F (1024°C) + | 500 | 260 | 46 | 800D | 427 | 55 | ||||

| Oil quench | 700 | 371 | 46/47 | 420F | 1900°F (1038°C) + | 300 | 149 | 52 | |||

| or air cool | 900C | 482 | 48 | Warm oil quench | 400 | 204 | 52 | ||||

| 1000C | 538 | 44 | 500 | 260 | 50 | ||||||

| 1100 | 593 | 31 | 600 | 315 | 50 | ||||||

| 416 Mod | 1800°F (982°C) + | 300 | 149 | 38 | 700 | 371 | 49 | ||||

| Oil quench | 500 | 260 | 37 | 800D | 427 | 49 | |||||

| 700 | 371 | 37 | 420F Mod | 1900°F (1038°C) + | 300 | 149 | 53 | ||||

| 900C | 482 | 35 | Warm oil quench | 400 | 204 | 50 | |||||

| 1000C | 538 | 30 | 500 | 260 | 48 | ||||||

| 1100 | 593 | 22 | 600 | 315 | 48 | ||||||

| 416 | 1800°F (982°C) + | 300 | 149 | 41 | 700 | 371 | 48 | ||||

| Oil quench | 500 | 260 | 39 | 800D | 427 | 48 | |||||

| 700 | 371 | 41 | UNS S42026 | 1920°F (1050°C)+ | 400 | 204 | 56 | ||||

| 900C | 482 | 36 | oil quench or | 500 | 260 | 54/55 | |||||

| 1000C | 538 | 31 | pressure gas | 600 | 315 | 53/54 | |||||

| 1100 | 593 | 26 | 431 | 1900°F (1038°C) + | 500 | 260 | 42 | ||||

| Oil quench | 700 | 371 | 42 | ||||||||

| 900C | 482 | 45 | |||||||||

| 1100C | 593 | 34 | |||||||||

| 420A | 1850°F (1010°C) + | 300 | 149 | 53 | 440A | 1900°F (1038°C) + | 300 | 149 | 56/57 | ||

| Warm oil quench | 400 | 204 | 50 | Warm oil quench | 400 | 204 | 56 | ||||

| 500 | 260 | 48 | 500 | 260 | 54 | ||||||

| 600 | 315 | 48 | 600 | 315 | 51/52 | ||||||

| 700 | 371 | 48 | 700 | 371 | 51 | ||||||

| 800D | 427 | 48 | 800D | 427 | 50 | ||||||

| 420B | 1900°F (1038°C) + | 300 | 149 | 52 | 440B | 1900°F (1038°C) + | 300 | 149 | 58/59 | ||

| Warm oil quench | 400 | 204 | 52 | Warm oil quench | 400 | 204 | 56/57 | ||||

| 500 | 260 | 50 | 500 | 260 | 53/54 | ||||||

| 600 | 315 | 50 | 600 | 315 | 53 | ||||||

| 700 | 371 | 49 | 700 | 371 | 54 | ||||||

| 800D | 427 | 49 | 800D | 427 | 54 | ||||||

| 420 Mod | 180°F (1010°C) + oil quench or pressure gas | 350 400 500 600 | 177 204 260 315 | 56/57 55 54 53 | |||||||

| 420X | 1900°F (1038°C) + | 300 | 149 | 52 | 440C | 1900°F (1038°C) + | 300 | 149 | 60 | ||

| Warm oil quench | 400 | 204 | 52 | Warm oil quench | 400 | 204 | 59 | ||||

| 500 | 260 | 50 | 500 | 260 | 57 | ||||||

| 600 | 315 | 50 | 600 | 315 | 56 | ||||||

| 700 | 371 | 49 | 700 | 371 | 56 | ||||||

| 800D | 427 | 49 | 800D | 427 | 56 | ||||||

| S42010 | 1900°F | 400 | 204 | 50 | 440F | 1900°F (1038°C) + | 300 | 149 | 60 | ||

| (1038°C) + Warm | 500 | 260 | 47 | Warm oil quench | 400 | 204 | 59 | ||||

| Oil Quench | 600E | 316 | 47 | 500 | 260 | 57 | |||||

| 700 | 371 | 48 | 600 | 315 | 56 | ||||||

| 850 | 454 | 48 | 700 | 371 | 56 | ||||||

| 800D | 427 | 56 | |||||||||

A Time at temperature depends on section size. Controlled heat treating atmosphere or alternate quench media may be used in accordance with good commercial practice.

B Temper at least one hour at indicated temperature and air cool. Large section sizes require longer time at temperature.

C Tempering in the range of 750/1050°F (399/566°C) results in decreased impact strength and reduced corrosion resistance.

D Tempering over 800°F (427°C) results in reduced corrosion resistance.

E Tempering above 600°F (316°C) results in reduced toughness.

TABLE 3 Examples of Selected Stainless Steels That Have Been Used for Surgical Instruments in Accordance with ISO 7153/1

| Type | Cutting Instruments | Non-Cutting Instruments |

|---|---|---|

| 303 | Chisels and gouges, bone curettes | probes |

| 304 | retractors | |

| 410 | tissue, forceps, dressing forceps, retractors, probes | |

| 420A | Bone rongeurs, conchotomes, bone cutting forceps, chisels and gouges, bone curettes, scissors with carbide inserts | forceps, retractors, probes, forceps with bow handles, branch forceps |

| 420B | bone rongeurs, scissors | |

| 420C | scissors, bone rongeurs, bone cutting forceps, conchotomes, scalpels, knives, bone curettes, chisels and gouges | |

| 420 Mod | bone rongeurs, conchotomes, bone cutting forceps, chisels and gouges, bone curettes, scissors with carbide inserts, scissors, scalpels, knives | tissue forceps, dressing forceps, retractors, probes, forceps, forceps with bow handles, branch forceps |

TABLE 4 Examples of Selected Stainless Steels That Have Been Used For Surgical Instruments in the United States

| Type | Cutting Instruments | Non-Cutting Instruments |

|---|---|---|

| 302 | knives, chisels, gouges, curettes | cannula, forceps, guides, needle vents, retractors, specula, spreaders, tendor passers, springs |

| 303A | chisels, curettes, knives | cannula, clamps, drills, forceps, handles, hammers, mallets, needle vents, punches, retractors, rulers, screws, skin hooks, specula, spreaders, suction tubes, tendon strips, tongs, tunnelers, probes |

| 304 | cannula, clamps, forceps, holders, handles, needle vents, retractors, specula, spreaders, suction tubes, tendon passers | |

| 316 | specula | |

| 410 | chisels, curettes, dissectors, osteotomes, reamers, scissors with inserts | clamps, clip applicators, elevators, forceps, hemostats, holders, needle holders, punches, retractors, skin hooks, sounds, spreaders, probes, dilators |

| 410X | curettes, dissectors, rongeurs | clamps, forceps, hemostats, holders, punches, retractors |

| 416A | chisels, curettes, dissectors | clamps, punches, retractors, skin hooks, spreaders |

| 420B | chisels, curettes, cutters, bone cutting forceps, knives, scissors, rongeurs, scalpels, skin punches, conchotomes | clamps, elevators, punches, rounds, dissectors, retractors, skin hooks, needles |

| 420FA | cutters | burrs |

| 431 | cheek retractors, insertion wrenches, orthopeadic instruments | |

| 440C | chisels, knives, osteotomes, scalpels | drills, retractors, spreaders, tongs |

| 420 Mod | chisels, curettes, cutters, bone cutting forceps, knives, scissors, rongeurs, scalpels, skin punches, conchotomes, ostoetomes, reamers | clamps, elevators, punches, rounds, dissectors, retractors, skin hooks, needles, cheek retractors, insertion wrenches, orthopaedic instruments, drills, spreaders, tongs, screwdrivers |

| 630 | reamers | |

| XM-16 | scissors | drills, needles |

| XM-13 | reamers, rasps | |

| S46500 | reamers, scissors, rasps, knives | Clamps, punches, impactor guides, strike plates, screwdrivers, hex drivers |

A It is not recommended that free-machining grades be used for critical portions of surgical instruments. Free machining grades should only be considered for instrument applications when appropriate steps can be taken during manufacture to minimize the inherent limitations of this class of alloys (see section 10.1)

B Types 420A, 420B, 420C, or UNS S42026 may be used depending on instrument design and application.

C Types 440A, 440B, or 440C may be used depending on instrument design and application.

ASTM International [astm]