Historical

SAE AMS 5590F-2010 (SAE AMS5590F-2010)

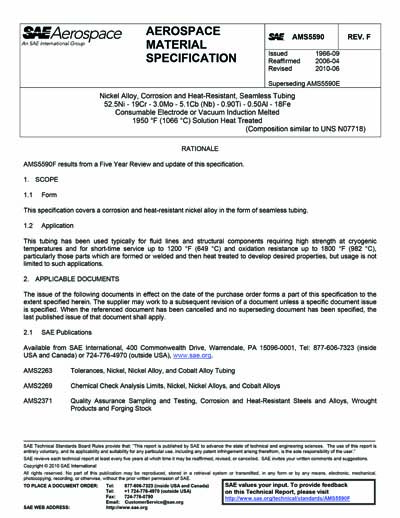

Nickel Alloy, Corrosion and Heat Resistant, Seamless Tubing 52.5Ni 19Cr 3.0Mo 5.1Cb (Nb) 0.90Ti 0.50Al 18Fe Consumable Electrode or Vacuum Induction Melted 1950\mDF (1066\mDC) Solution Heat Treated ( Reaffirmed: Apr 2006 )

This specification covers a corrosion and heat resistant nickel alloy in the form of seamless tubing. This tubing has been used typically for fluid lines and structural components requiring high strength at cryogenic temperatures and for short-time service up to 1200 degrees F (649 degrees C) and oxidation resistance up to 1800 degrees F (982 degrees C), particularly those parts which are formed or welded and then heat treated to develop desired properties, but usage is not limited to such applications.

Society of Automotive Engineers [sae]