Historical

SAE AMS 5662M-2004 (SAE AMS5662M-2004)

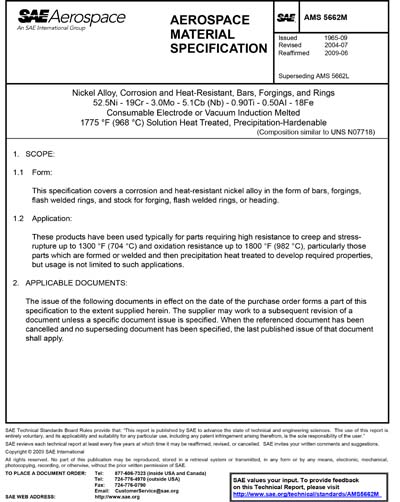

Nickel Alloy, Corrosion and Heat Resistant, Bars, Forgings, and Rings 52.5Ni 19Cr 3.0Mo 5.1Cb (Nb) 0.90Ti 0.50Al 18Fe, Consumable Electrode or Vacuum Induction Melted 1775\mDF (968\mDC) Solution Heat Treated, Precipitation Hardenable ( Reaffirmed: Jun

This specification covers a corrosion and heat resistant nickel alloy in the form of bars, forgings, flash welded rings, and stock for forging flash welded rings or heading. These products have been used typically for parts requiring high resistance to creep and stress-rupture up to 1300 \mDF (704 \mDC) and oxidation resistance up to 1800 \mDF (982 \mDC), particularly those parts which are formed or welded and then precipitation heat treated to develop required properties, but usage is not limited to such applications.

Society of Automotive Engineers [sae]