Historical

SAE AMS 5919A-2013 (SAE AMS5919A-2013)

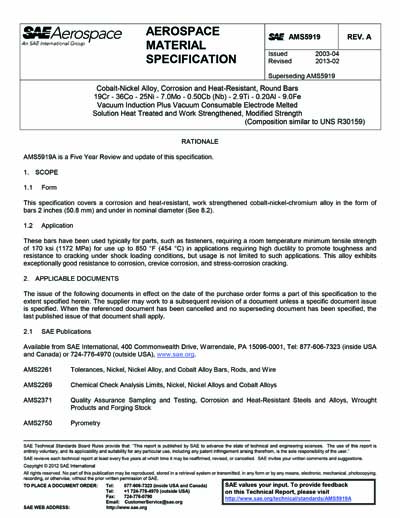

Cobalt-Nickel Alloy, Corrosion and Heat-Resistant, Round Bars 19Cr 36Co 25Ni 7.0Mo 0.50Cb (Nb) 2.9Ti 0.20Al 9.0Fe Vacuum Induction Plus Vacuum Consumable Electrode Melted Solution Heat Treated and Work Strengthened, Modificed Strength

This specification covers a corrosion and heat-resistant, work strengthened cobalt-nickel-chromium alloy in the form of bars 2 inches (50.8 mm) and under in nominal diameter.

These bars have been used typically for parts, such as fasteners, requiring a room temperature minimum tensile strength of 170 ksi (1172 MPa) for use up to 850 \mDF (454 \mDC) in applications requiring high ductility to promote toughness and resistance to cracking under shock loading conditions, but usage is not limited to such applications. This alloy exhibits exceptionally good resistance to corrosion, crevice corrosion, and stress-corrosion cracking.

Society of Automotive Engineers [sae]