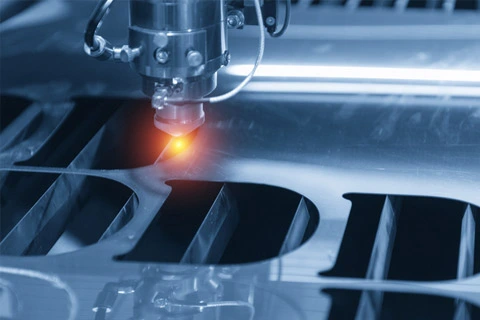

Lasers in Manufacturing and Welding

Lasers are very commonly used in manufacturing processes and welding. These standards cover a wide range of topics in this industry including safety, testing and recommended practices.

ANSI Z136.1 and Z136.9 Combination Set

Safe Use of Lasers and Safe Use of Lasers in Manufacturing Environments

This combination set contains ANSI Z136.1-2014 and ANSI Z136.9-2013

ANSI Z136.9-2013

American National Standard for Safe Use of Lasers in Manufacturing Environments

This standard provides recommendations for the safe use of lasers and laser systems that operate at wavelengths between 180 nm and 1 mm. Laser applications in the manufacturing environment include, but are not limited to, material processing, fabrication, laser alignment, leveling, inventory, metrology, and machine vision.

ANSI B11.21-2006 (R2020)

Safety Requirements for Machine Tools Using Lasers for Processing Materials

This standard applies to machine tools using a laser for processing materials, and its associated equipment. It describes the hazards generated by such machines and states the protective measures to be incorporated into such machines. The standard also contains requirements for the information provided with such machines.

ISO 11553-1:2020

Safety of machinery - Laser processing machines - Part 1: Laser safety requirements

This document describes laser radiation hazards arising in laser processing machines, as defined in 3.7. It also specifies the safety requirements relating to laser radiation hazards, as well as the information to be supplied by the manufacturers of such equipment (in addition to that prescribed by IEC 60825). Requirements dealing with noise as a hazard from laser processing machines are included in ISO 11553 3:2013. This document is applicable to machines using laser radiation to process materials. It is not applicable to laser products, or equipment containing such products, which are manufactured solely and expressly for the following applications: photolithography; stereolithography; holography; medical applications (per IEC 60601-2-22); data storage.

AWS C7.2M:2010

Recommended Practices for Laser Beam Welding, Cutting and Allied Processes

This document presents recommended practices for laser beam welding, cutting, drilling, and transformation hardening. It is intended to cover common applications of the process. Processes definitions, safe practices, general process requirements and inspection criteria are provided.

AWS C7.4/C7.4M:2017

Process Specification and Operator Qualification for Laser Beam Welding

This specification on laser beam welding discusses applicable specifications, safety, requirements, fabrication, quality examination, equipment calibration and maintenance, approval of work, and delivery of work.

ISO 15614-11:2002

Specification and qualification of welding procedures for metallic materials - Welding procedure test - Part 11: Electron and laser beam welding

This European Standard specifies how a welding procedure specification for electron or laser beam welding is qualified by a welding procedure test.

This standard is a part of a series of standards, details of this series are given in prEN ISO 15607, annex A.

It defines the conditions for the execution of welding procedure qualification tests and the limits of validity of a qualified welding procedure for all practical welding operations within the range of variables listed in clause 8.

Tests shall be carried out in accordance with this standard together with additional tests when specified.

This standard applies to metallic materials, irrespective of the shape of the parts, their thicknesses, manufacturing method (rolling, forging, casting, sintering, etc.) and their heat treatment. It covers unlimitedly the production of new parts and repair work.

ISO 22826:2005

Destructive tests on welds in metallic materials - Hardness testing of narrow joints welded by laser and electron beam (Vickers and Knoop hardness tests)

ISO 22826:2005 specifies the requirements for hardness testing of transverse sections of narrow laser and electron beam welded joints in metallic materials. It covers Vickers and Knoop hardness tests in accordance with ISO 6507-1 and ISO 4545, respectively, with test forces of 0,098 N to just under 98 N (HV 0,01 to just under HV 10) for the Vickers hardness test and test forces up to and including 9,8 N (just under HK 1) for the Knoop hardness test.

It is applicable to welds made with or without filler wire. It may not be applicable to the testing of wider hybrid laser/arc welds.

ISO 13919-1:2019

Electron and laser-beam welded joints - Requirements and recommendations on quality levels for imperfections - Part 1: Steel, nickel, titanium and their alloys

This document gives requirements and recommendations on levels of imperfections in electron and laser-beam welded joints in steel, nickel, titanium and their alloys. Three levels are given in such a way as to permit application for a wide range of welded fabrications. Quality level B corresponds to the highest requirement of the finished weld. The levels refer to production quality and not to the fitness-for-purpose of the product manufactured.

This document applies to electron and laser beam welding of:

— steel, nickel, titanium and their alloys;

— all types of welds welded with or without additional filler wire;

— materials equal to or above 0,5 mm thickness for electron and laser beam welding.

The purpose of this document is to define the dimensions of typical imperfections which can be expected in normal fabrication. It can be used within a quality system for the production of welded joints. It provides three sets of dimensional values from which a selection can be made for a particular application. The quality level necessary in each case is defined by the application standard or the responsible designer in conjunction with the manufacturer, user and/or other parties concerned. The quality level is expected to be prescribed prior to the start of production, preferably at the enquiry or order stage. For special purposes, additional details may need to be prescribed.

When significant deviations from the joint geometries and dimensions stated in this document are present in the welded product, it is necessary to evaluate to what extent the provisions of this document can apply.

Metallurgical aspects, e.g. grain size, hardness are not covered by this document.

This document does not address the methods used for the detection of imperfections. This document is directly applicable to visual examination of welds and does not include details of recommended methods of detection or sizing by other non-destructive means. There are difficulties in using these limits to establish appropriate criteria applicable to non-destructive testing methods, such as ultrasonic, radiographic and penetrant testing, and they can need to be supplemented by additional requirements for inspection, examination and testing.